Product Description

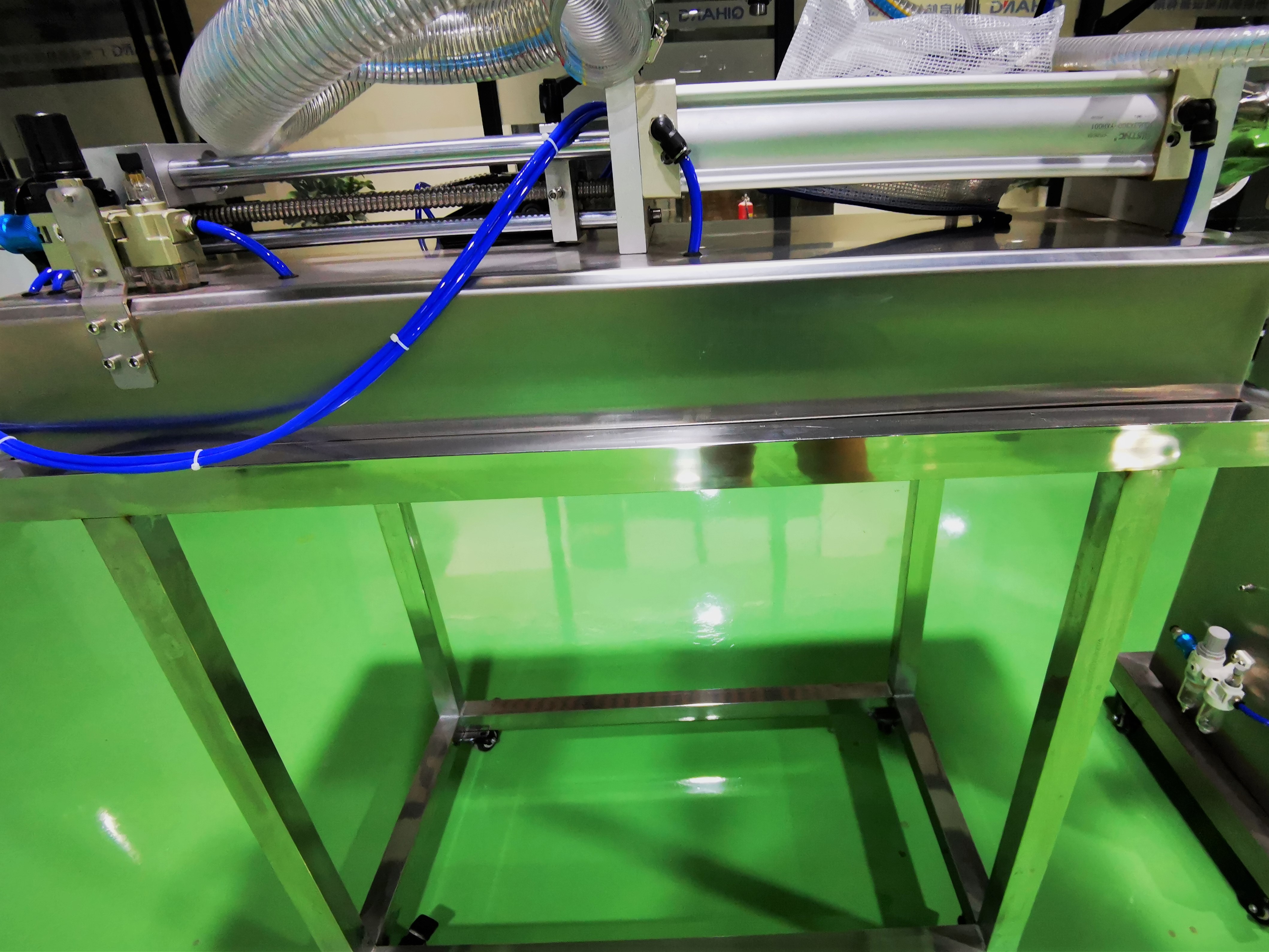

1000ml cosmetic tube suction mascara double row gmp lotion bottle filling machine

Product Feature

The paste filling machine is suitable for Cosmetic Cream,honey,syrup,etc.

The machine's Characteristics: the filling accuracy is high, the error rate is 1%.

We can be customized three or four heads filling machine.

Product Specification/Models

specification:

| Powe supply |

200/110V 50/60HZ |

| Sir pressure |

0.4-0.9mpa |

| Power |

50-100W |

| Filling speed |

10-60bottles/min |

| Filling accuracy |

≤1% |

| Filling volumes range |

5-100ml 10-300ml 50-500ml 100-1000ml 500-3000ml 1000-5000ml |

Cosmetic Filling Machine introduction:

◆ Automatic bag feeding, filling, sealing, code printing and outputting

◆ The parts that contact materials are all made of stainless steel 316, meeting GMP requirements.

◆ Different filling machines are selected according to the nature of materials. The standard configuration is electronic gear pump, and the optional configuration is pneumatic piston pump, which is suitable for filling of facial mask liquids of relatively high viscosity.

◆ No filling is carried out if there is no bag. No sealing is carried out if there is no bag. The seal is not sticky to the bag.

◆ Operation is controlled by PLC+LCD. The equipment parameters, output and error information are clearly seen on the touch screen.

◆ Digital display of temperature control.

◆ The electric and pneumatic components are all products of international famous brands.

♦Introduction♦

Piston pneumatic Filler is of wide applicability and can be used for doing filling of creams and liquids in the fields of dailychemistry, food and beverage, pharmacy, chemistry and so on.Inquire the manufacturer about other uses. Any damage due to misuse is out of limitation of warranty of the manufacturer. Such risks shall be borne by the user solely.Strictly following the instruments is a part of operation requirements.

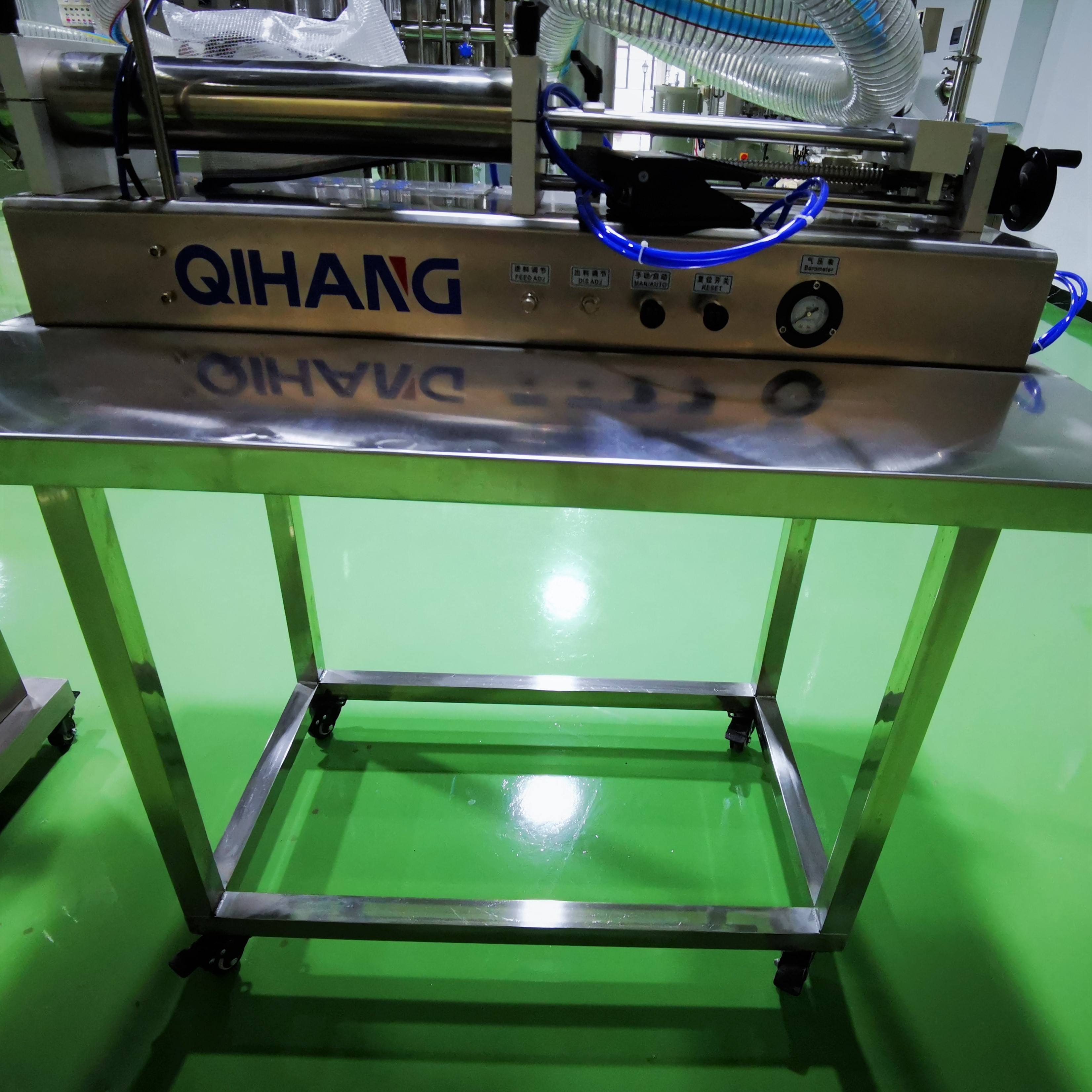

This machine is of reasonable structure, reliable performance and accurate quantification. It applies pneumatically-driven structure. The shell and all the parts connected with filling materials are made of stainless steel (SS304 is used for standard ones and SS316 can also be customized). The inner walls of main parts are mirror-polished in roughness Ra≤0.2-0.4µm, which conforms to the requirements of GMP certification. Therefore, it is rustless and corrosion resistant. In addition, the user can adjust the filling volume and

speed within the type limitation as required.

♦Characteristics♦

1. Be used for filling with particulate matter sauce,paste,liquid and other material;

2. Some of the materials used 304 stainless steel;

3. Full pneumatic control, easy to operate,remove and clean; Ideal equipment for filling inflammable, explosive materials.

♦Technical Parameter♦

| Fillable range |

5-100ml,10-300ml,50-500ml,100-1000ml, |

| Filling speed |

≤3000pcs/Hour |

| Air pressure |

0.4MPa |

| Material |

Stainless steel |

| Automatic Grade |

Semi-Automatic |

| Filling accuracy |

±1% |

| Air pressure range |

4-6kg/cm2 |

| Power |

pneumatic |

| Filling head |

Single head or Double Head or Customized |

| Shipping package size |

950×420×380mm |

♦Packing List♦

| Seal ring for discharge piston shaft |

2 pcs |

| Anti-Drip Seal Ring |

4pcs |

| Seal ring for discharge end |

2pcs |

| Seal ring for changeable nozzle |

2pcs |

| Piston Seal Ring |

2pcs |

| Yoke Seal Ring |

2pcs |

| Philips Screwdriver |

1pcs |

| Allen Key(6,8) |

Each 1 pcs |

| Open end wrench |

1pcs |

| Power wire |

1 strip |

| Pedal Switch |

1pcs |

| Instructions |

1 copy |

| Warranty Card |

1 copy |

| Certificate of comformity |

1 copy |

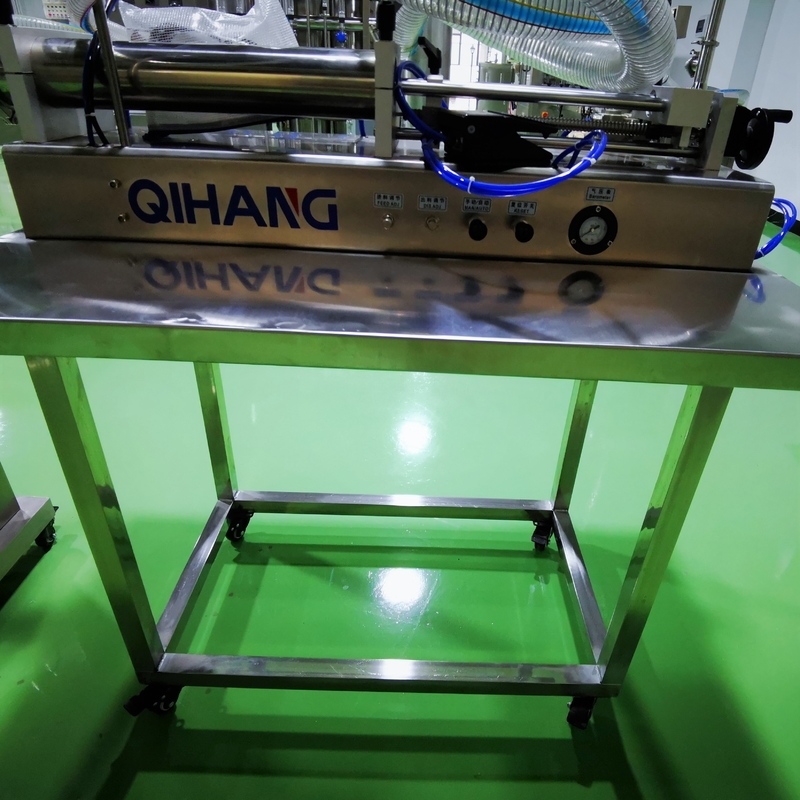

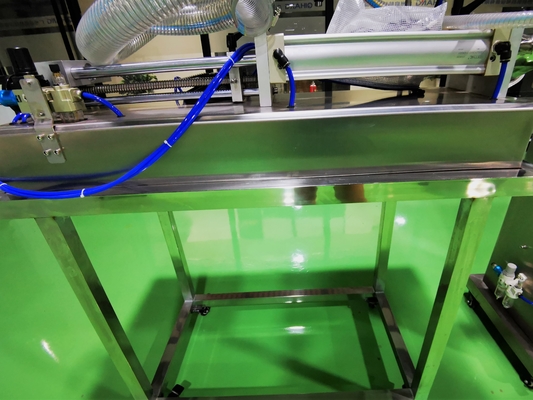

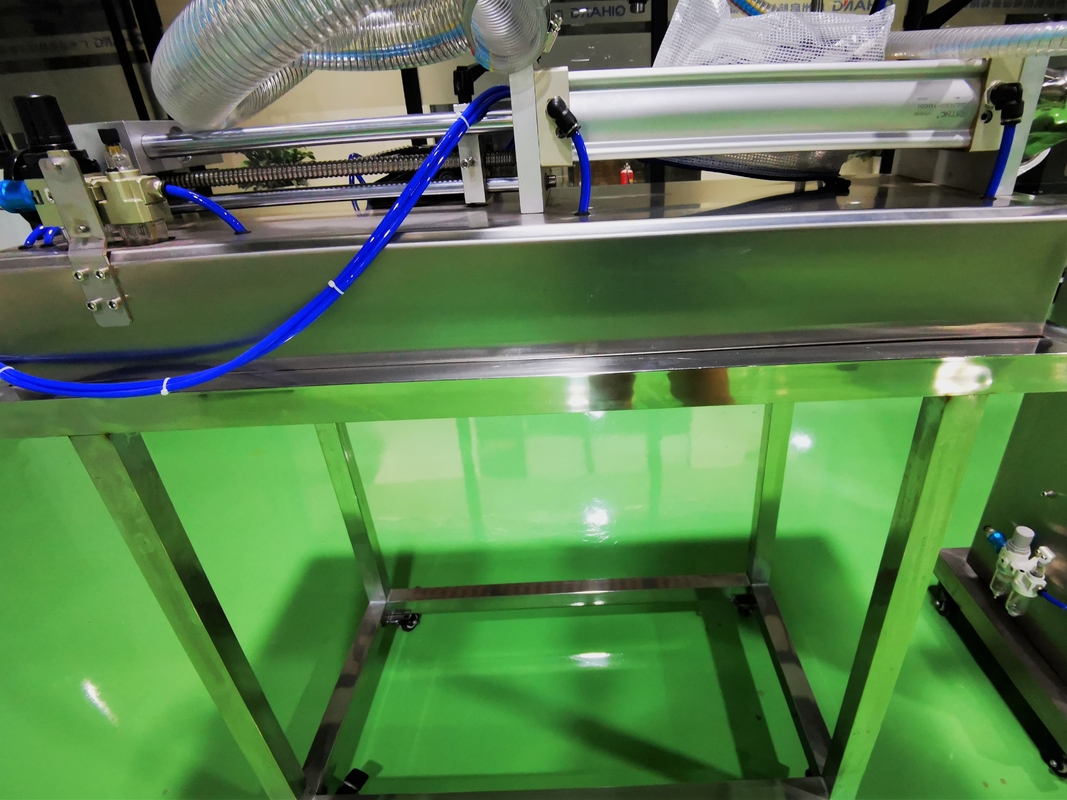

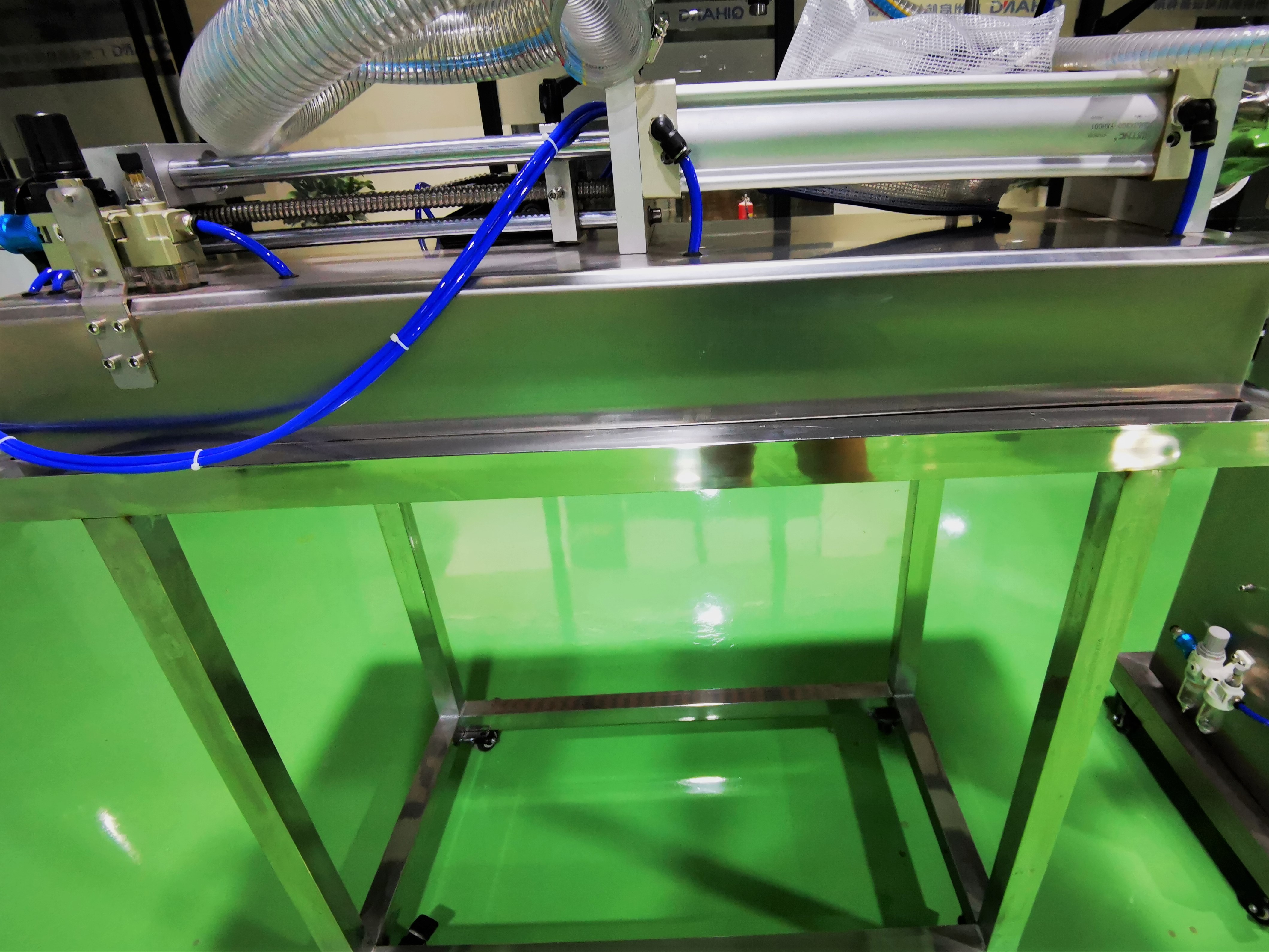

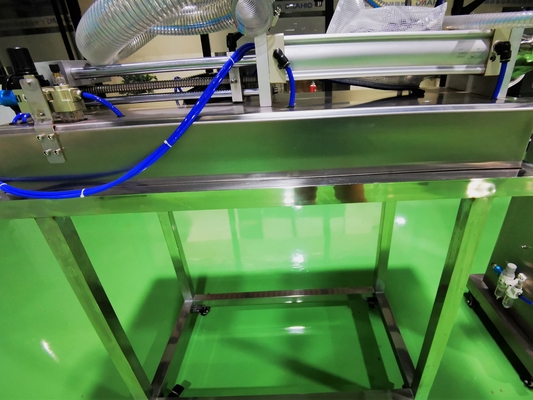

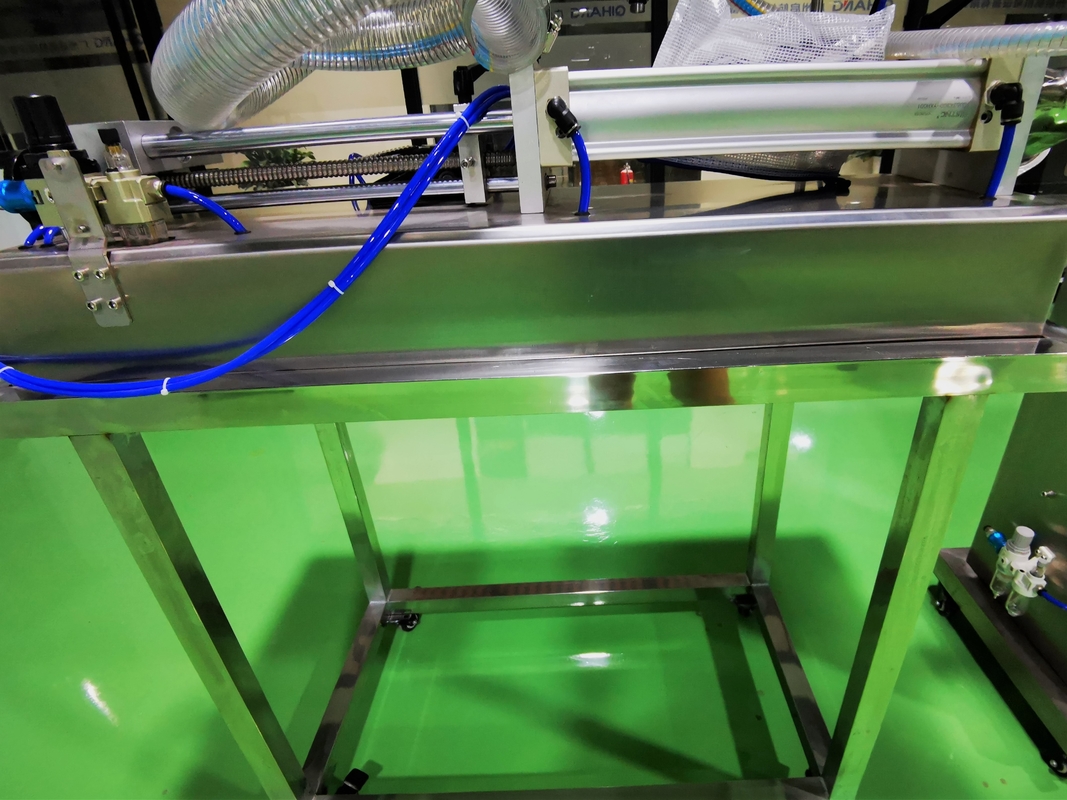

PICTURE

Advantage of product:

A. High Accuracy---- Pneumatic control besides hardware positioning, which has high filling precision that can be controlled between0.1%-1%(water).

B. Anti-explosion-----All adopt compressed air as the control, so they are quite suitable for the use in the request of anti-explosion environment.

C. Certainly Safe---Will not happen the leakage of electricity and no need to connect the ground wire.

D. Customized type----Any type, material and filling capacity can be customized according to your request.

Qihang according to wishes designed to meet both the technical requirements and investment plan to match the best solution. And relying on their own understanding of the technology industry and the cosmetics industry professional self-control team, committed to the professional digital solutions to provide the best quality customer service.

PROJECT CASES

Manage ltem: vacuum homogenizing emulsifiers, high shear liquid detergent mixers, reverse osmosis ion water devices, various water injection, liquid and ointment semi-automatic and automatic filling production lines, round and flat bottles automatic and semi-automatic labeling machines, perfume whole-set production lines, laboratory equipment, flow lines, etc.

FAQ

Q1: Are you factory ?

Of course yes, we are factory producing Vacuum Packaging Machinery ,Band Sealer,

Carton Sealer etc since 1988. We are Top3 Supplier in Wenzhou ,China.

Q2: Do you have CE Certificated ?

Yes. CE ,ISO9000 approved.

Q3: What’s payment do you support?

T/T, L/C at sight, Western Union is accepted. For regular order, 30% downpayment ,

70% balance before ship.

Q4: What’s lead time ?

Machines always be finished on 7days.

Q5: Do you support OEM/ODM?

Yes, we can develop the styles base on customer’s requirement.

Q6: Do you offer Certification Of Original?

Yes , we can.

Our Services

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Protection of your sales market, ideas of design and all your private information.

3. Well-trained and experienced staffs to answer all your enquires in fluent English.

4. Distributionship are offered for your unique de./.sign and some our current models;

5. OEM&ODM,any design and idea can be customized if required

6. Warranty is 1 years since shipping day,24 hours solve if you get problem.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!