Product Description

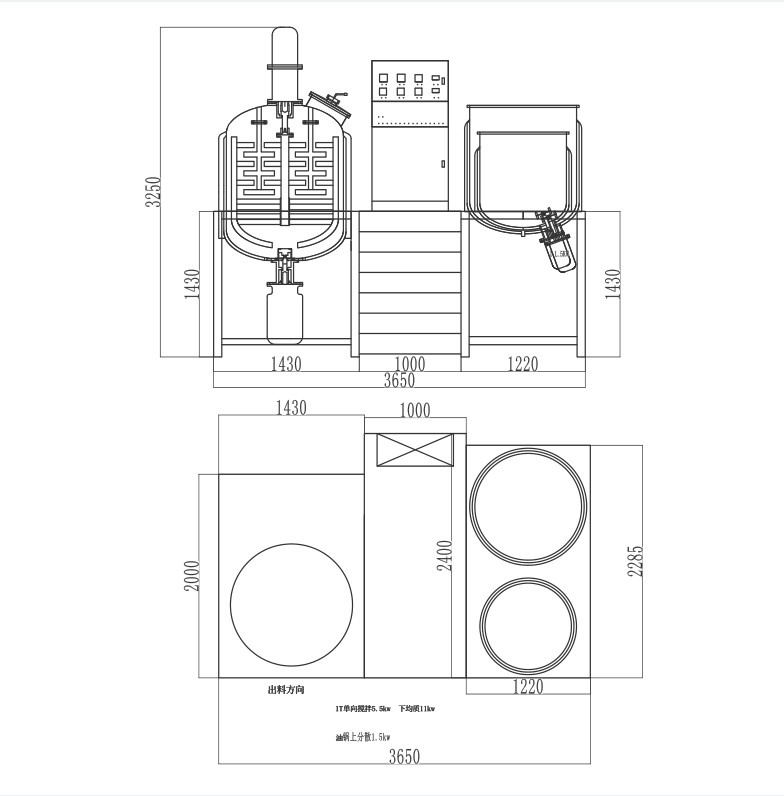

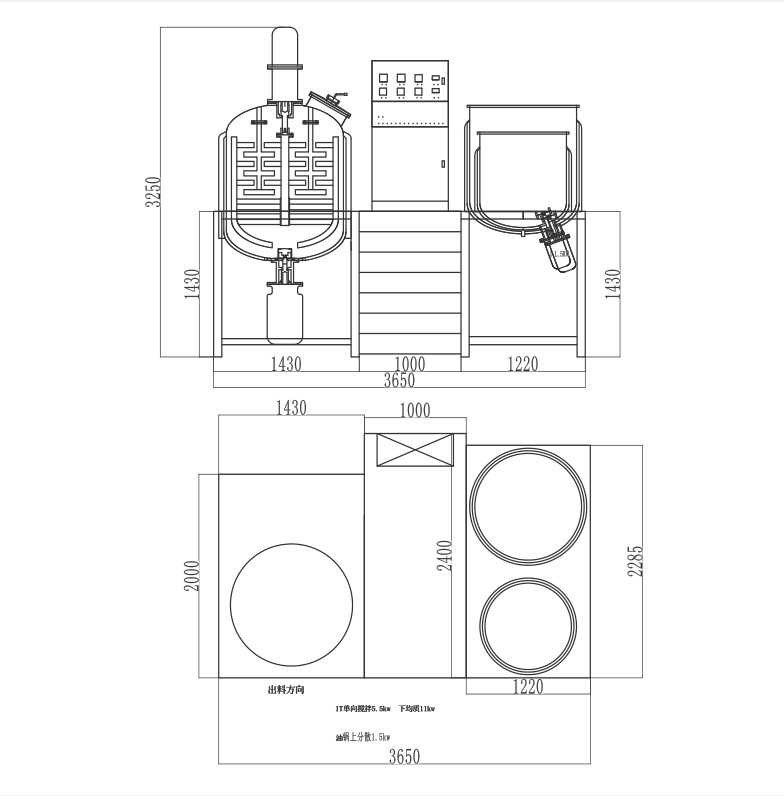

500L cosmetic cream vacuum emulsifying homogenizer mixer

Vacuum Emulsifying Homogenizer Mixer Introduction

1, The triple mixing adopts the imported frequency inverter for speed adjustment, which can meet different technological demands.

2, The homogenizing structure is made through German techology. The machine adopts the improted double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 3500rpm and the high shearing fineness can reach 0.2-5um.

3, The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum materials vacuum sucking can avoid dust.

4, The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

5, The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish whcih meet the GMP standard.

6, According to process requirement, the tank body can heating and cooling the electric heating.

7, To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the international standards.

Technical Parameter of the Vacuum Emulsifying Homogenizer

| Model |

AW-A100 |

AW-A300 |

AW-A500 |

| Volume of Emulsifying Pot |

100L |

300L |

500L |

| Vacuum pressure of Emulsifying Pot |

-0.09 Mpa

|

| Temperature of Emulsifying Pot |

≤120 °C

|

| Pressure of Jacket |

0.09Mpa

|

| Speed of Scraping Plate Blender |

0-83 r/min

|

| Speed of Homogenizer |

0-3040 r/min

|

| Voltage |

50Hz

380V±10%-15%

|

It is suitable for production of ointment and cream products in cosmetic and pharmaceutical plants. The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Product Description

* This machine is for mixing cosmetic liquid or cream products,like shampoo, liquid hand washing soap, liquid detergent ect

* It can be without heating, electric heating and steam heating

* With platform or without platform

* With homogenizer or without homogenizer

* If heating needed, the material will be inner layer, SUS316L, middle layer, SUS201, outter layer, SUS304

Product introduction

Small vacuum homogeneous emulsifying machine is suitable for various type of ointment, honey products, small, pilot or a board, it is the cosmetics, pharmaceutical production enterprises laboratory indispensable experimental tool. Equipment has complete function, reliable quality.

This equipment is a set of vacuum deaeration, mixing, homogenizing, heating, electric control and other functions in one, equipment is composed by the vacuum homogenizing emulsifying pot, vacuum system, a lifting system. It is also according to the requirements of the production process supporting oil and water pot.

Characteristic of the Vacuum Emulsifying Homogenizer

The main boiler capable of automatic lifting, dumping of discharge, to sure maximum material completely discharging, configuration homogenizer or homogenizer can be variable frequency speed.

Our service

-

Warranty time: one year, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.

-

Commissioning services: the product's installation and commissioning at the demand side, our engineers will not leave there untill get your agreement.

-

Training services: our engineers will train your staff to operate it during the period of installation and commissioning, and they will not leave there until your staff can operate it properly and normally.

-

Maintenance services: any malfunction happened, once you enquiry us, we will reply you within 48 hours except the special reasons.

-

Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

-

Certificate services: we can provide related certificates to customers freely according to the request of customers.

-

Inspection services: you can ask the third part inspection company or your inspector to inspect the products before shipment.

-

The file: the Manual Specification, report of the material which used to the equipment and others documents related to the GMP authentication information will be provided by us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!