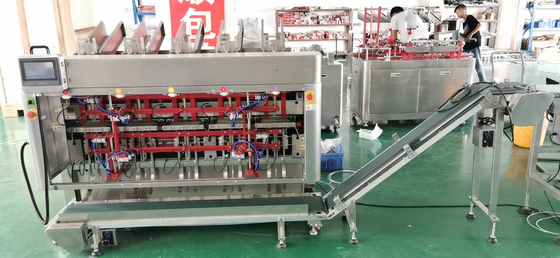

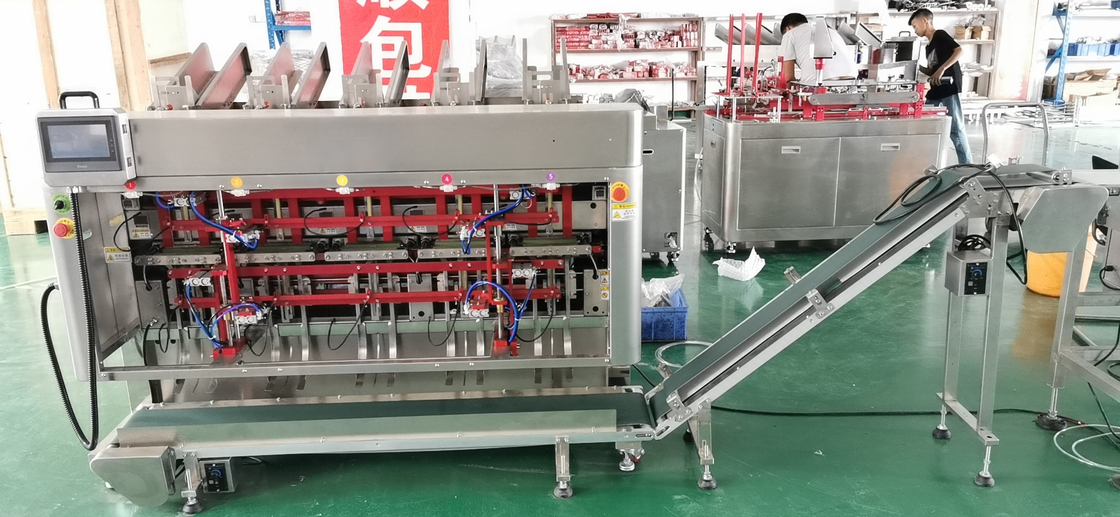

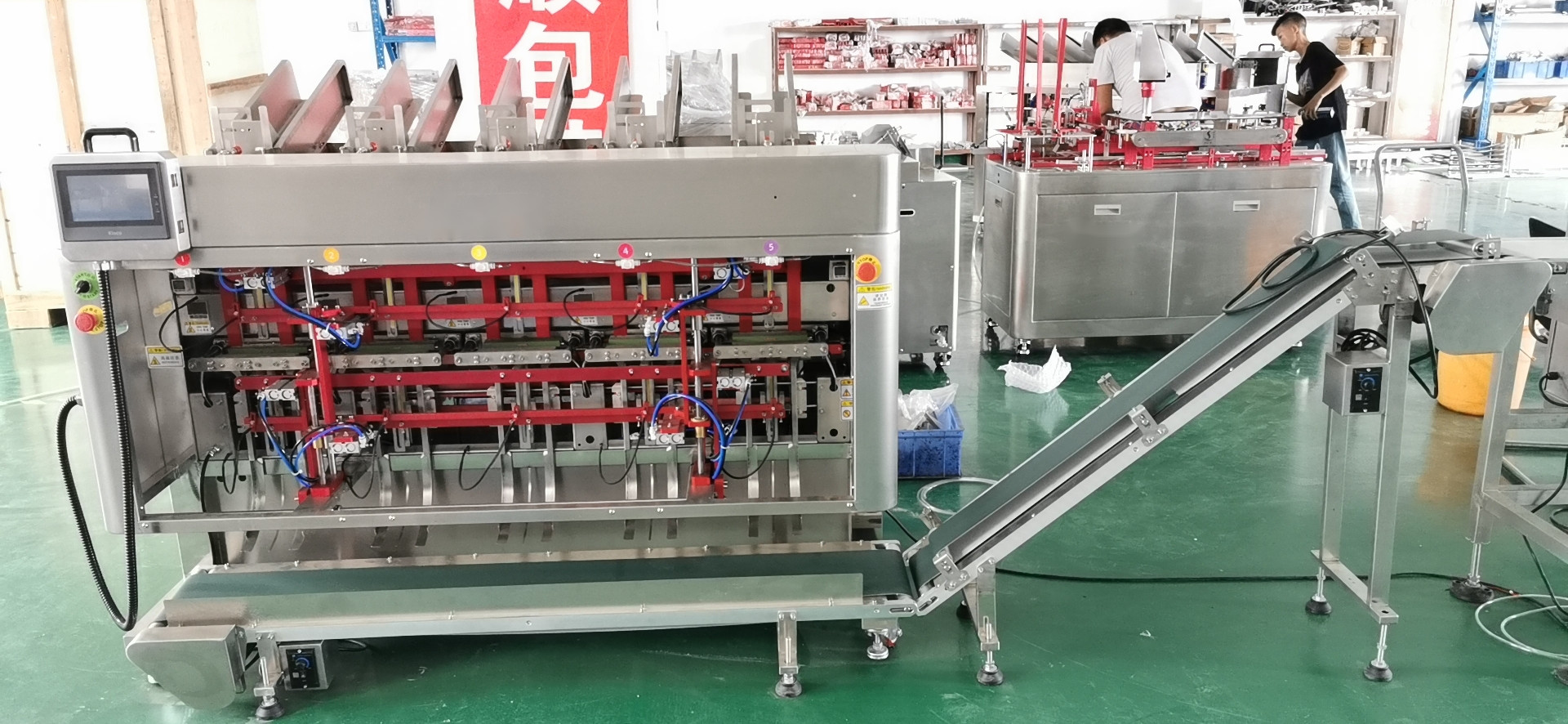

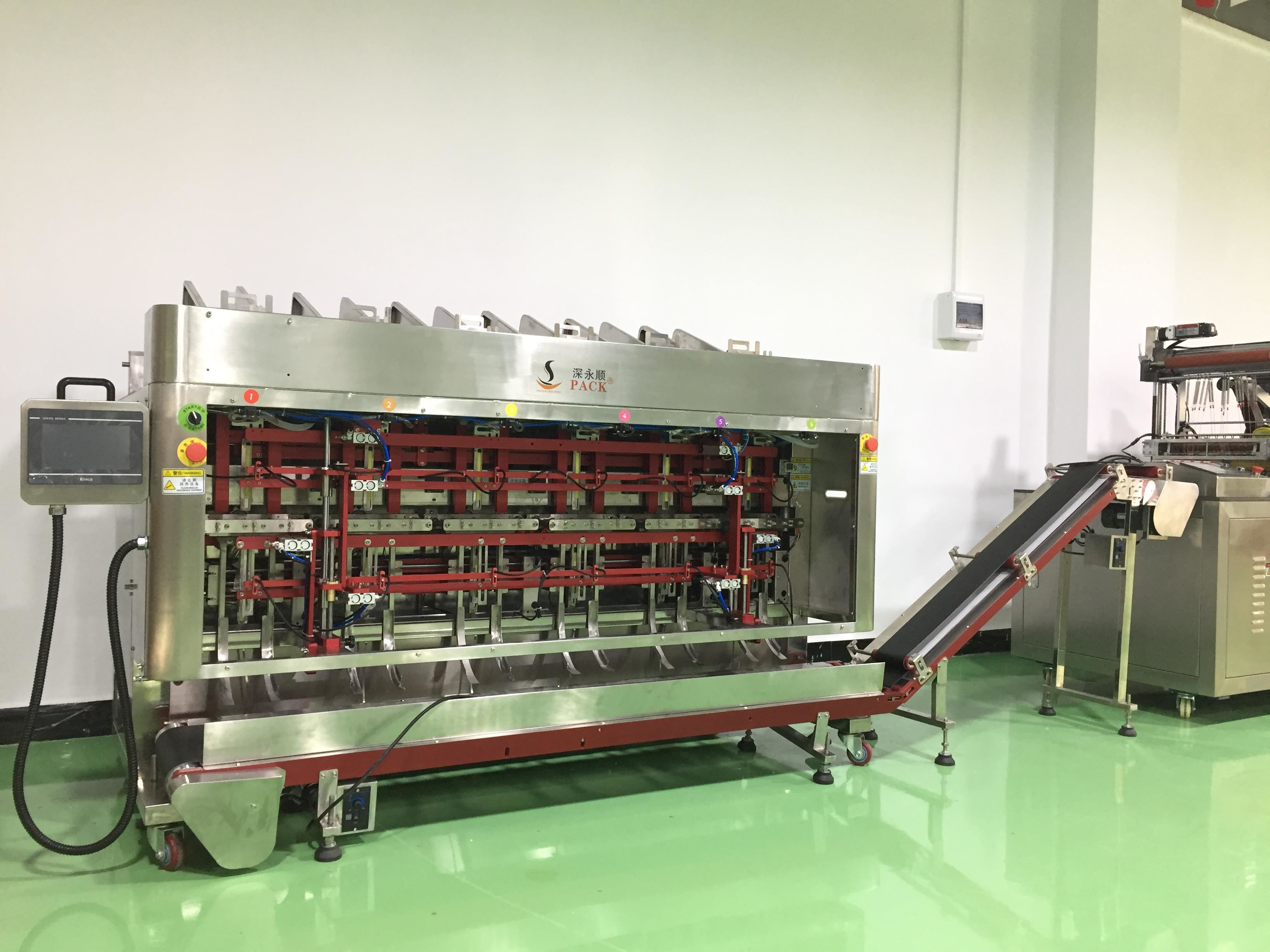

Product Description

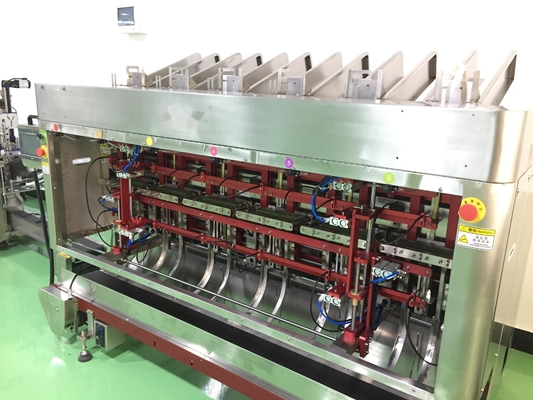

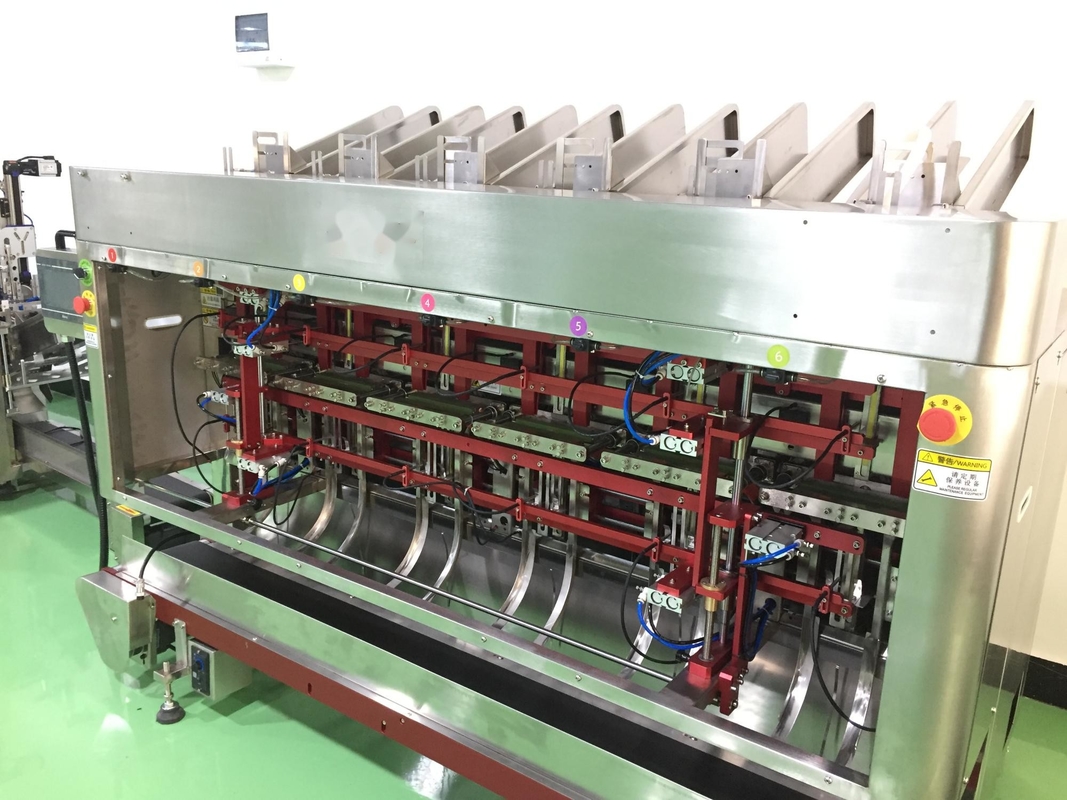

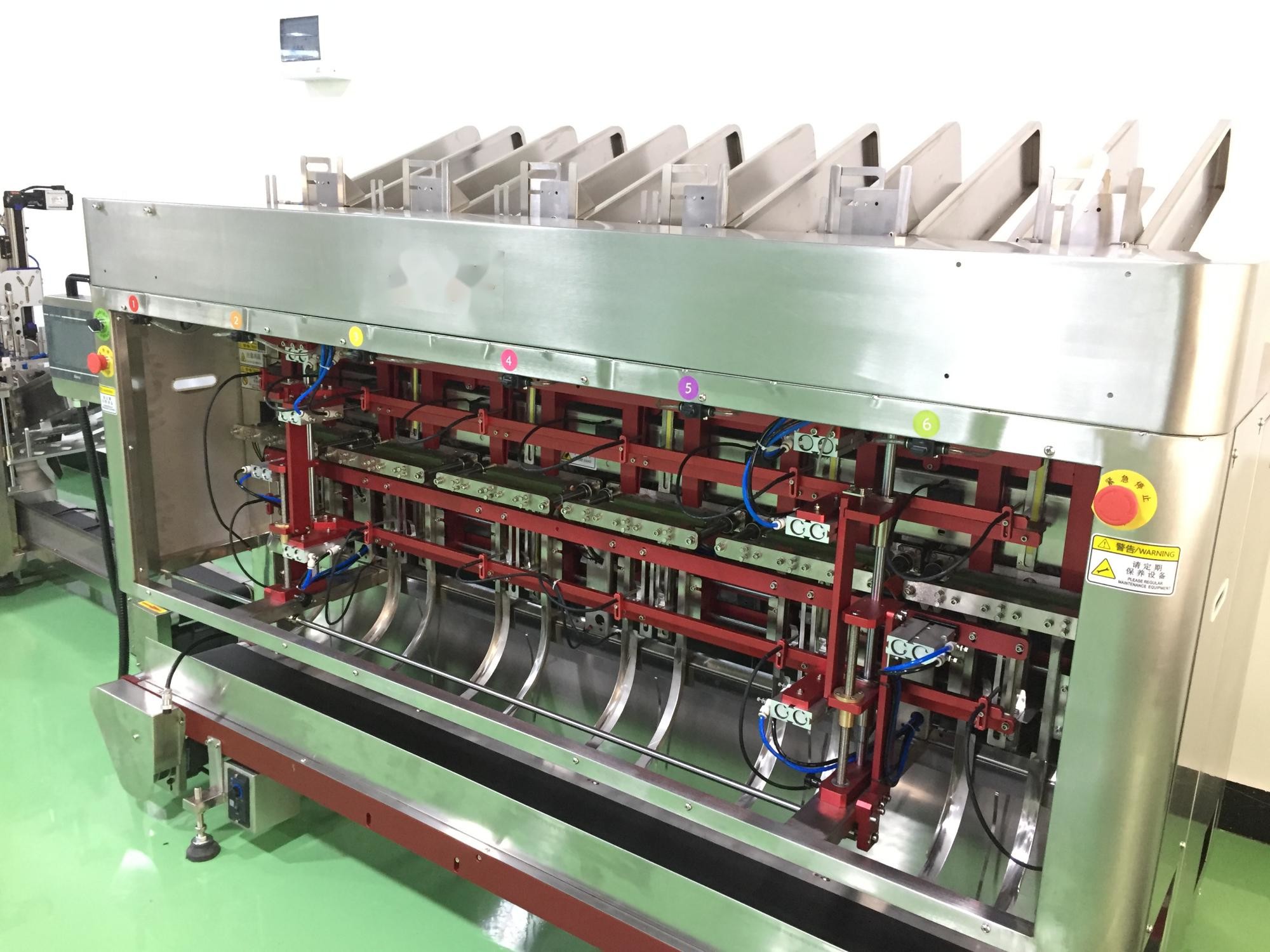

Temperature Controller Face Mask Sachets Filling Sealing Machine Press The Button

Surface plate operation

1.1 Operation Panel Operation Instructions

1) Power switch

When the whole machine is powered on, the power switch is rotated 90 ° clockwise. At this time, the panel parameters can be set and the machine can operate. When the power switch is switched off, the power switch is rotated 90 ° and the whole machine is disconnected.

2) Start/stop switch

To start/stop the running switch of the device, press the button to start the device, the device starts, and the button light is on. When the device is stopped, press the button again. The device stops running and the button lamp is off.

3) Press the button for emergency stop

In case of malfunction or emergency, press this button and the machine will stop immediately. And display "Emergency stop pressed!" in the fault display area. To restart the machine, unlock this button (press open and right turn) until that "Emergency stop has been pressed!" has been disappeared.

1.2 Operation instructions of temperature controller (PID adjustment)

1) The temperature controller is used to control the heating temperature of the heat packer. The temperature setting range is 0 ~ 1000℃. The dividing number of the matched temperature sensor is: Type K.

The first display: current value (PV) or setting data symbol E5CSL : includes setting value, setting data

- Second display: set value (SV) or set data

- Deviation display: Relationship between the current value and the set value

▲:The light is on when the difference between the current value and the set value is greater than + 5.0 ℃/F

▼:When the difference between the current value and set value is greater than -5.0℃/F, the light is on

▄:When the difference in value between current value and set value within the greater than or less than 5.0 ℃ / F, the light on

When automatically adjusted, the attenuation indicator of the bright light will flash

- The light is on when the first display is setting temperature (E5CSL only)

- The alarm output function is ‘on’ when the lamp is on and ‘off’ when the lamp is off

- The control output function is on when the lamp is on and off when the lamp is off

- When it RUN, the light off; when it STOP, the light on

- Menu button. Use this button to switch menus

- Mode key. Use this key to switch the setting data in the setting menu

- Down key, use this key to reduce the set value

- Up key, use this button to increase the value of the setting before

- Hold down for more than 3 seconds to enter the protection menu while adjusting the menu mode on the operation menu, and hold down for more than 1 second in the protection menu mode to return to the operation menu.

- Simultaneously press and hold the setting for more than 2 seconds to execute/cancel the automatic adjustment

- hold down at the same time for more than 2 seconds to set RUN/STOP

- When the action setting key will automatically adjust the execution/cancellation setting to invalid, it will be invalid

- Invalid when RUN/STOP is set to invalid by using the action setting key

Technical Features

| Production process |

automatic bag down → bag opening → filling → sealing → output |

| Number of filling heads |

6 filling heads |

| Production speed |

6000-7200 bags/hour |

| Bag width |

120-170mm |

| Length of bag |

140-220mm |

| 6 filling mode |

gear pump |

| Equipment power supply |

220V/ 1pH |

| Equipment power |

7.5KW |

- PLC and touch screen control system, stable performance, easy to operate.

- No bag, no filling, no bag, no sealing.

Main configuration

| Kinco |

Touch screen |

| PLC |

Hechuan |

| Thermostat |

Omron |

| Electric eye |

Dedicated |

| Solenoid valve |

CDK |

| Frame |

Stainless steel |

Input type: Thermocouple

| Input |

Set value |

Range(℃) |

Range(℉) |

| K |

0 |

-200-1300 |

-300-2300 |

| 1 |

-20.0-500.0 |

0.0-900.0 |

| J |

2 |

-100-850 |

-100-1500 |

| 3 |

-20.0-400.0 |

0.0-750.0 |

| T |

4 |

-200-400 |

-300-700 |

| 5 |

-199.9-400.0 |

-199.9-700.0 |

| R |

6 |

0-1700 |

0-3000 |

| S |

7 |

0-1700 |

0-3000 |

Reference temperature for general packaging materials

|

Packaging materials

|

Setting temperature |

|

Paper/polyethylene;

Pure aluminum/polyethylene

|

160~180℃ |

| Cellophane/polyethylene |

110~130℃ |

| Paper/polyethylene |

170~200℃ |

| Polypropylene/polyethylene |

120~140℃ |

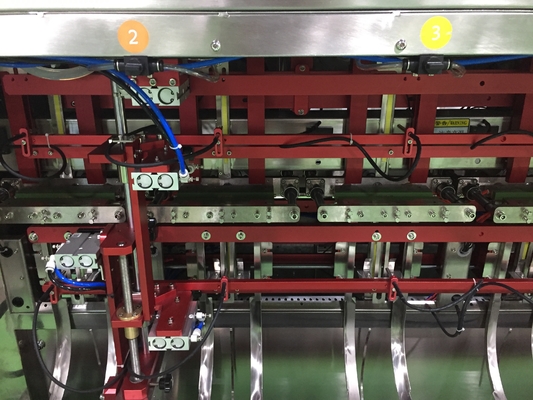

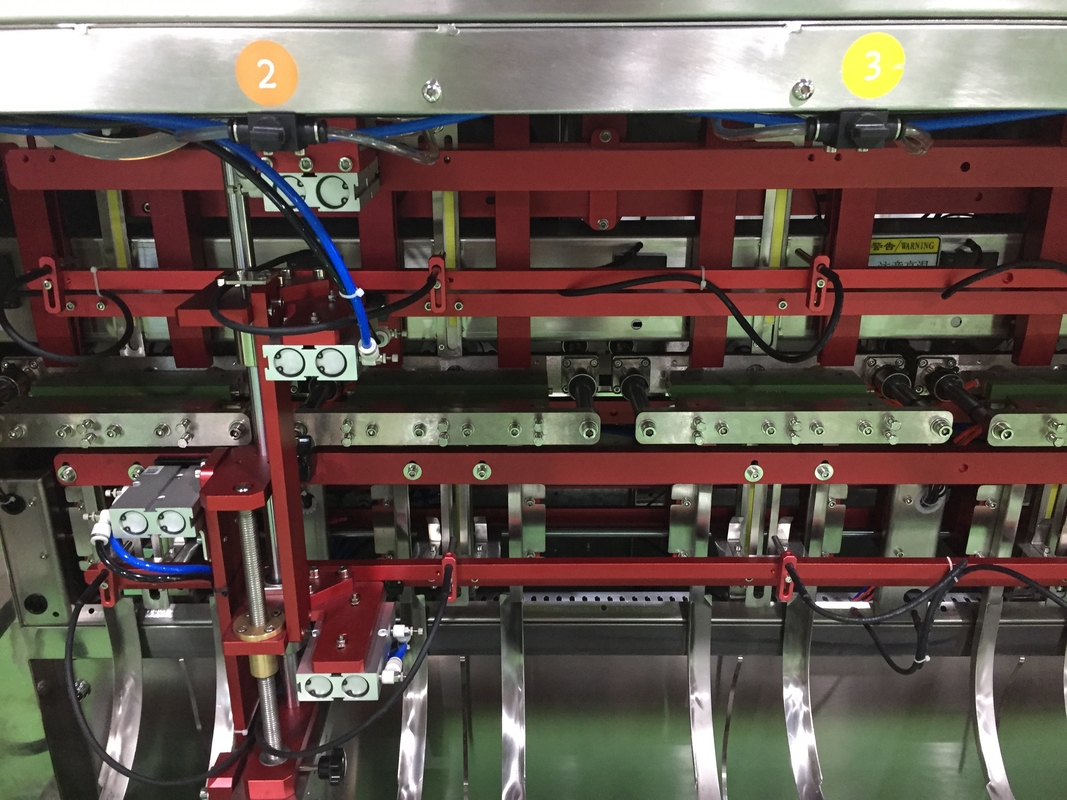

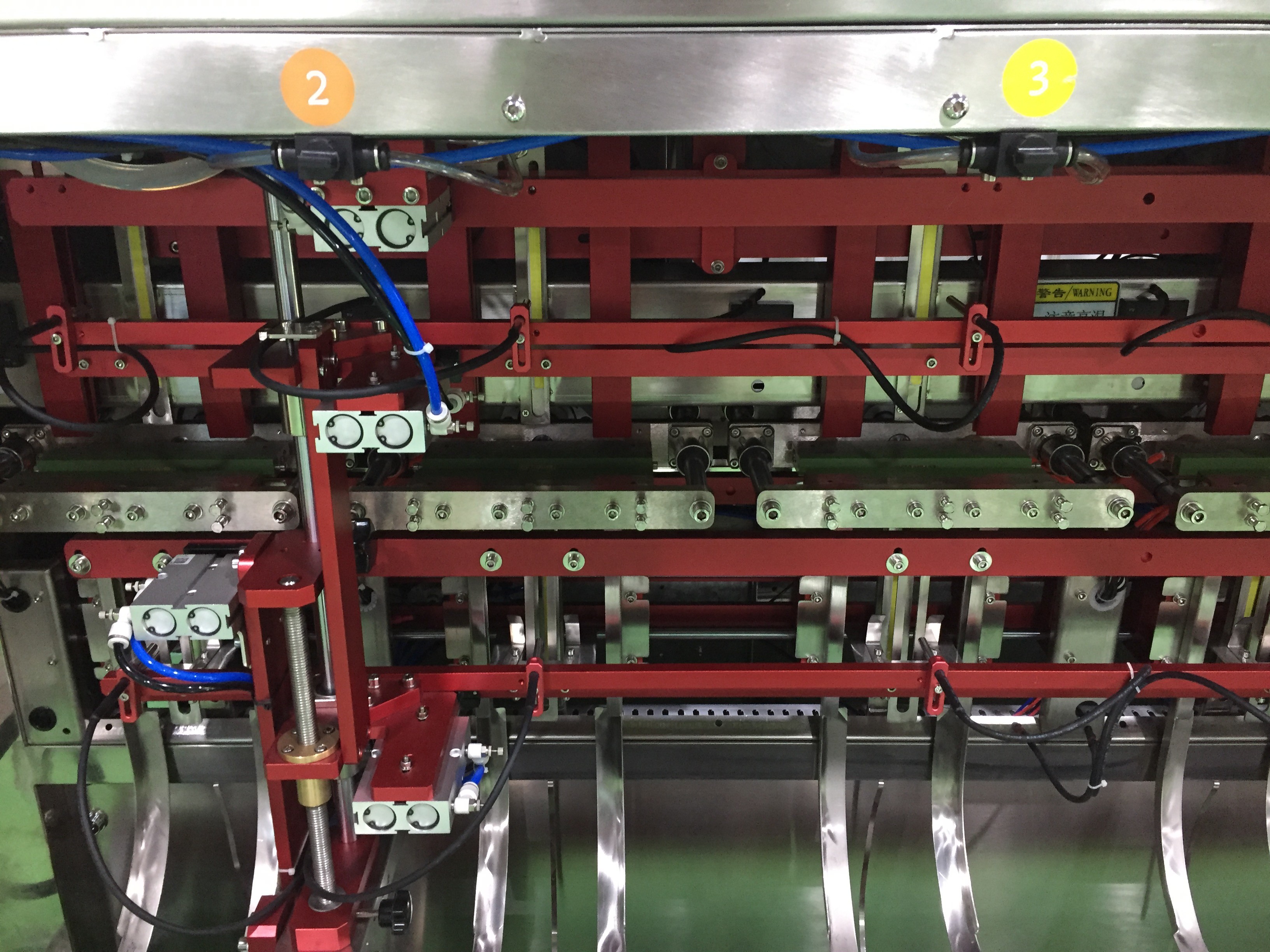

Adjustment of opening height

First, put the bag in the filling place. The pocket must be adjusted 2-3 millimeters higher than the suction cup, but it is at least 5 millimeters lower than the filling pipe. The guides on both sides of the bag should be 3-6 mm wider than the bag. It should not be too tight or too loose. Too tight, it is easy to clip bags, too loose, the bags are easy to clip.

Adjustment of sealing height

Adjust the height of the lower baffle by adjusting the black handle on the screw rod. The bag will rise or fall with the lower baffle to adjust the sealing height. The left black handle can adjust the width of the guide grooves on both sides of the sealing part, which should be 3-6 mm wider than the bag.

FAQ

1.what's the delivery time?

it's a big machine, we will manufacture according to the orders. usually, it's no in stock, it need about 90 days for the automatic face mask making machine. The actual time will depend on the condition of our workshop,so please order it a little early before your timing, thank you!

2.how many container request for this machine?

Usually, one pcs 40HC container is ok, it's depend by your order. thank you!

3.Are you a manufacturer?

Yes,We have been packaging machinery over 14 years.

4.what about the payment term ?

Mostly 30%T/T in advanced,the rest need paid before shipping.

5.What information should i let you know if i want to get a quotation?

-- Quantity

-- What's the detailed size of face mask?

-- What's the detailed size of pouch,and pouch shape?

-- What's the folding way of face mask?

-- how many ml of the essence?

-- What's the inner material, how many layers? such as 3layer( PP/spunlace nonwoven/Pearlized BOPP)

6.what's your advantages ?

-- 14 years experience:We have been in making machinery for 14 years.

-- Customers all over the world

-- Certificate: CE certificate

-- Fast reply:Our team will reply you soon.

-- After-sale service:We have a after sale department , service for your problems and dealing with spare parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!