Product Description

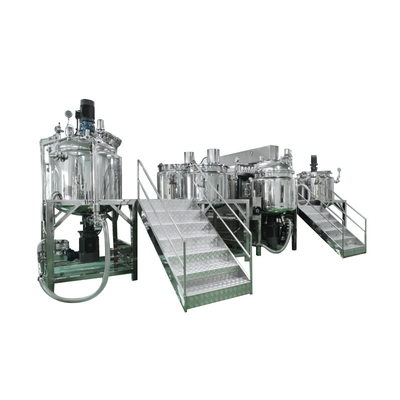

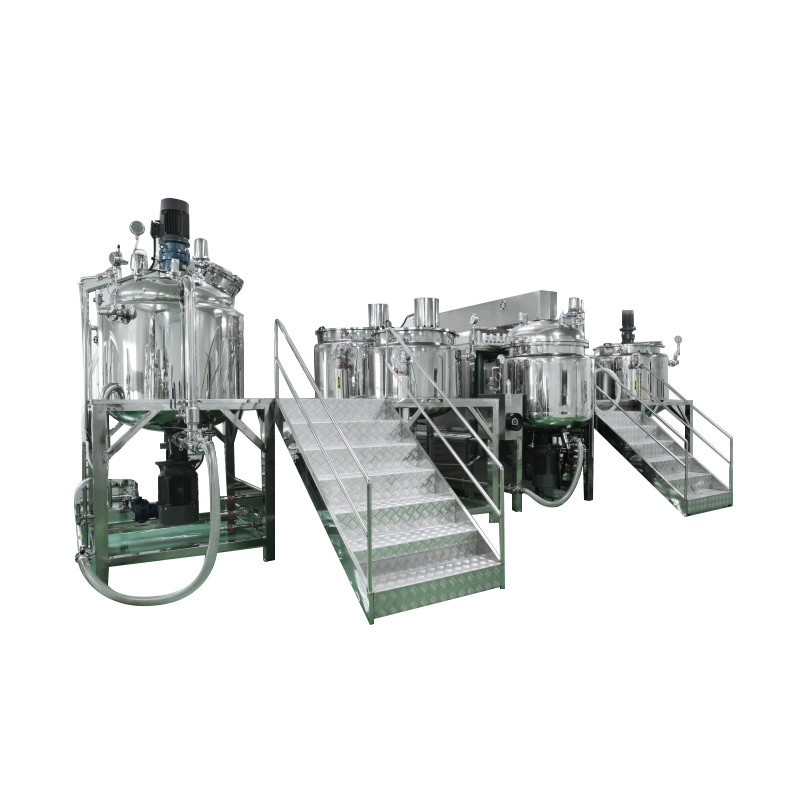

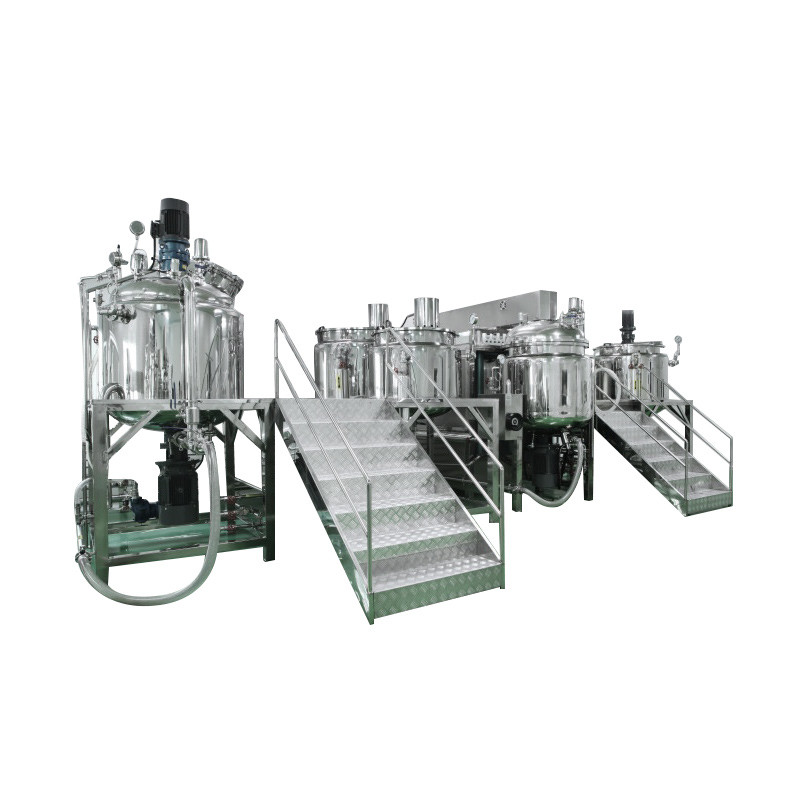

Homogenizer Mixer Cosmetic Cream Mixer Liquid Soap Mixer Emulsifying Pot And Mixing Pot

Product Description

This type of liquid-washing stirring pot product is suitable for the cosmetic industry, and is mainly used for vacuum homogeneous stirring.

Main technical parameter of the Mixing Tank

| Item |

Model |

Capacity |

Mixer power |

Mixer speed |

Homogenizer power |

Homogenizer speed |

The method of the heat |

| L |

kw |

rpm |

kw |

rpm |

Steam or the electric |

| 1 |

100 |

100 |

1.1 |

0~65 |

1.5 |

3000 |

| 2 |

200 |

200 |

1.5 |

0~65 |

3 |

3000 |

| 3 |

500 |

500 |

2.2 |

0~65 |

4 |

3000 |

| 4 |

1000

|

1000 |

2.2-4 |

0~65 |

7.5 |

3000 |

| 5 |

1500 |

1500 |

4-5.5 |

0~65 |

11 |

3000 |

| 6 |

2000 |

2000 |

5.5 |

0~65 |

11 |

3000 |

| 7 |

3000 |

3000 |

7.5 |

0~65 |

15 |

3000 |

| 8 |

5000 |

5000 |

11 |

0~65 |

22 |

3000 |

Application of the Mixing Tank

The liquid mixing and blending tank is applied to reaction agitating of liquid scrubbing, textile assistant, medicine chemistry, food, beverage, perfume, perfumery compound,etc.

Also applied to the products of homogenization,emulsifying,particle dispersion,etc.

Feature of the Mixing Tank

1: Blending system adopts single-direction or double-direction wall scraping blending to satisfy different technological requirement.

2: Frequency conversion speed adjustment.

3: Material can be heated or cooled according to technological requirements

4: Electric heating or steam heating.

5: Various forms of blending vanes are suitable for production of different types of products.

6: Made of imported SUS304 OR SUS316L stainless steel. The tank body and pipe are subjected to mirror polishing.

7: Bottom installation type dispersing head and FLUKO pipeline type emulsifying head are optional to speed up dissolution and emulsification of materials.

8: The stainless steel electric control cabinet can completely supervise the operation of equipment, and disply such data as temperature and blending rotation speed, etc.

9: High -speed disperse(homogenizer) strongly mixed decentralized thick, solid, liquid.

Type stirring blade were left to right:

single way mixing internal & external circulation, double way mixing internal & external circulation, single way mixing & internal circulation, double way mixing & internal circulation, single way mixing & external homogenizer, double way mixing & external homogenizer

Body Material

Inner wall: stainless steel 316

Jacket and outer layer: stainless steel 304

Both inner and outer are polished and handled by special light treatment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!