Product Description

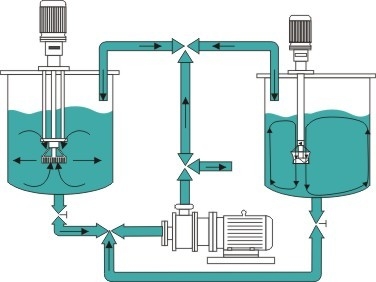

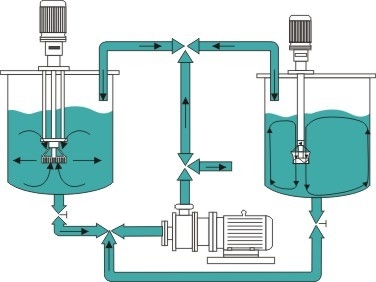

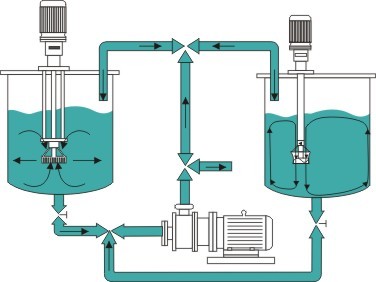

Stainless Steel Continuous Stirred Tank Reactor, Liquid Makeup Product Line

Product Description

Stainless steel 1000L-20000L continuous stirred tank reactor industrial batch reactor price is a new type of chemical engineering equipment we manufacture on the basis of our constantly introducing advanced technology and applying it into improving our products.

Specification of the Stirring Reactor

| Model |

Norminal Capacity

(L)

|

Heating Power (KW*PCS) |

Oil volume (L) |

Inner diameter

(mm)

|

Outer diameter (mm) |

Supporting screw diameter (mm) |

n-d |

Expander capacity

(L)

|

Motor power (KW) |

Stirring rate

(r/min)

|

Weight (KG) |

| 50L |

50L |

2*4 |

96 |

Φ400 |

Φ600 |

Φ828 |

4-25 |

10 |

1.1 |

80 |

270 |

| 100L |

100L |

2*6 |

127 |

Φ500 |

Φ700 |

Φ928 |

4-25 |

10 |

1.1 |

80 |

340 |

| 300L |

300L |

4*6 |

218 |

Φ800 |

Φ1000 |

Φ1148 |

4-25 |

20 |

2.2 |

80 |

700 |

| 500L |

500L |

4*9 |

269 |

Φ900 |

Φ1100 |

Φ1252 |

4-25 |

20 |

3 |

80 |

930 |

| 1000L |

1000L |

4*12 |

400 |

Φ1200 |

Φ1400 |

Φ1588 |

4-30 |

40 |

4 |

80 |

1610 |

| 2000L |

2000L |

4*15 |

850 |

Φ1400 |

Φ1600 |

Φ1840 |

4-30 |

40 |

5.5 |

80 |

2010 |

| 3000L |

3000L |

4*15 |

1015 |

Φ1600 |

Φ1750 |

Φ2040 |

4-35 |

40 |

7.5 |

80 |

2590 |

| 4000L |

4000L |

5*15 |

1226 |

Φ1600 |

Φ1750 |

Φ2070 |

4-36 |

40 |

11 |

80 |

3160 |

| 5000L |

5000L |

4*18 |

1400 |

Φ1800 |

Φ2000 |

Φ2320 |

4-36 |

40 |

15 |

80 |

4000 |

Stirring Reactor Application

It is widely applied for producing pharmaceuticals, construction materials, chemicals, foodstuffs, pigments and resinic products.

Performance Characteristics and Advantages of the Stirring Reactor

1. rapid heating,

2. corrosion resistance,

3. high temperature resistance,

4. non environmental pollution,

5. automatic heating without boiler and simple & convenient operation.

Configuration

1. Volume: 50L~50000L (series of specifications), can be customized as per customer requirement;

2. Components: autoclave body, cover, jacket, agitator, shaft seals, bearing and driving device;

3. Optional Reactor type: Electric heating reactor, Steam heating reactor, Heat conduction oil heating reactor;

4. Optional Agitator type: Anchor type, Frame type, Paddle type, Impeller type, Vortex type, Propeller type, Turbine type, Push-in type or Bracket type;

5. Optional Structure type: Outer coil heating reactor, Inner coil heating reactor, Jacket heating reactor;

6. Optional tank material: SS304, SS316L, Carbon steel;

7. Optional inner surface treatment: mirror polished, anti-corrosion painted;

8. Optional outer surface treatment: mirror polished, machinery polished or matt;

9. Optional Shaft Seal: Packing seal or Mechanical seal;

10. Optional feet form: three pyramidal form or tube type;

Siemens motor:

- Higher efficiency levels reduce energy consumption and directly enable users to save costs.

- The higher protection level (IP55) ensures safe and reliable use by customers.

Delta inverter:

- High energy-saving machine efficiency

- Efficient input and output power factor

- Highly flexible expansion method

- Low overall investment and maintenance costs

High shear homogenization:

- High uniformity, good polishing, energy saving, stable operation

- Speed of fast homogenizing stirrer:0-3500r/min (frequency conversion speed regulation)

Mixing part (Material: SUS316, GMP standard):

- Speed: slow wall scraping stirrer speed: 0-63r/min (frequency conversion speed regulation)

- Siemens motor + reducer provide strong and stable power for mixer, panasonic brand frequency inverter, PTFE material scrape blade.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!