Product Description

In this section, you will learn about the machine that will assist you to complete your packaging line. Let’s begin with the definition.An automatic capping machine assists in faster and better placement of caps on top of different containers.

What do I mean?

It means that you can use the machine to place, fit and tighten caps on different containers.The containers can range from beverage bottles, medicine bottles among others. Although there are many cap types out there as you will learn, below are some examples of the caps.

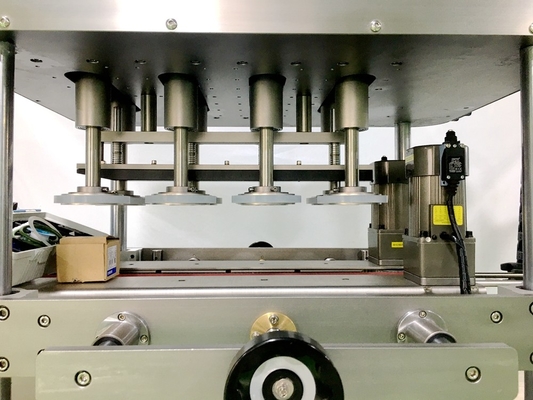

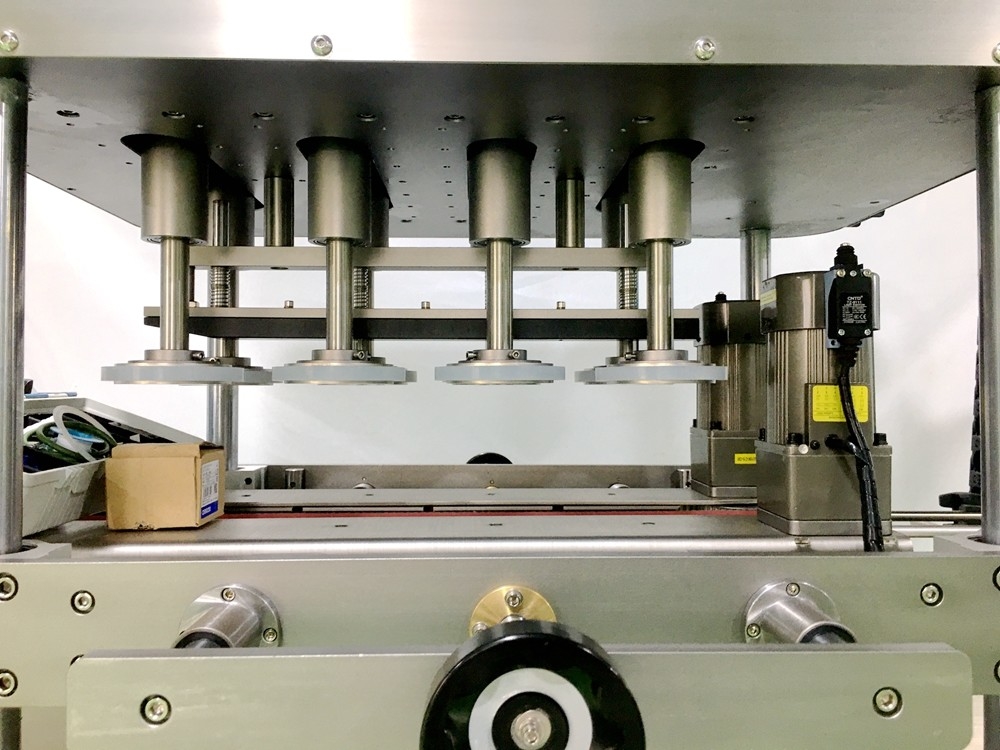

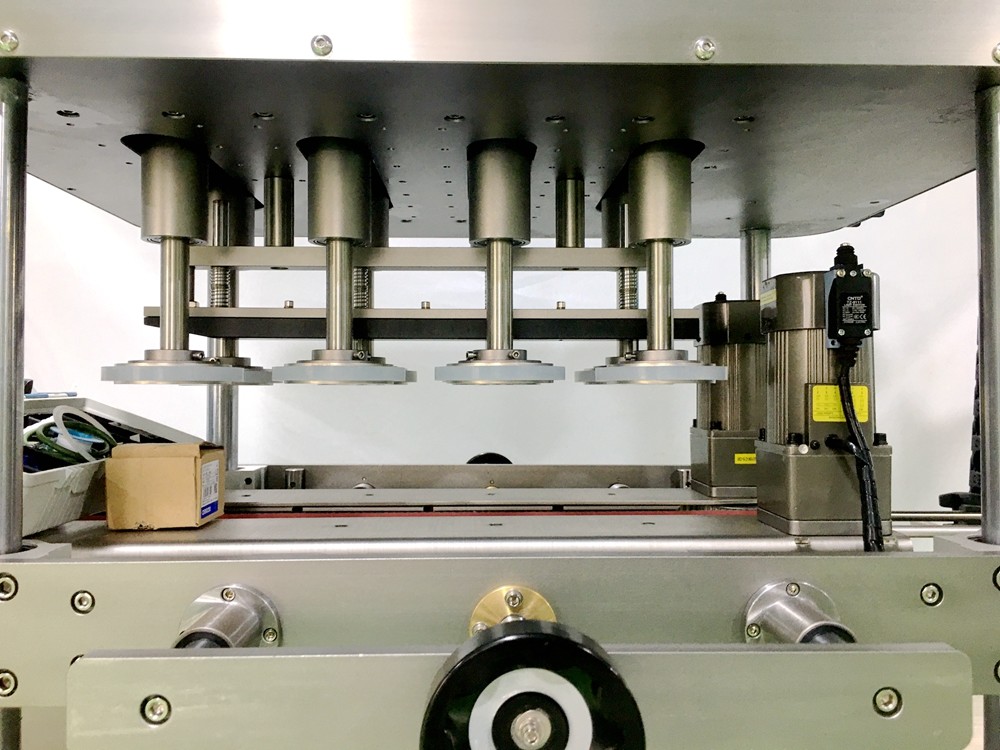

Automatic capping machine

- Screw caps which have threads to secure the cap to the container such as plastic screw caps

- Crown caps

- Press-on closures which hold in place using undercuts and beads instead of threads

- The capping machine will automatically handle the containers and strengthen the caps to rates depending on the type of machine.

- As an operator, you will have to adjust the capping rates of the machine accordingly.

- I guess you might wonder why you need to have an automatic capping machine.

- Of course, it has its benefits and demerits too.

- The machine comes with a lot of benefits that you will realize as soon as you begin using it.

- You will realize an increase in production output.

- Apart from that, you will see an increase in production efficiency through accurate torque values.

- It will help in eliminating labor fatigue and prevents unnecessary injuries

According to the size range of the caps

Whenever you are going for an automatic capping machine, there is an important question you should ask yourself.

What is the size of the range caps that I intend to use?

Caps usually range in diameter from very small e.g. 5 mm to very large 120 mm.

A great size range is often impractical to work on in a capping machine.

Sizes of bottle caps

URS for Automatic Capping Machine

User requirement specifications are the standards that you need to satisfy before operating an automatic capping machine.

These standards will enhance the level of operation and besides that, keep you safe.

Apart from that, they will guide you on what to do to ensure smooth operations.

Let’s have a look at some of the things you need to know.

First, you need to make sure that you have all the right attire in place.

The attire will protect you from injuries in case of accidents.

It can protect your skin from burns in case you were dealing with corrosive fluids.

Apart from that, you need to have knowledge of operating the machine.

The higher the level of experience the better. In case you don’t have the relevant knowledge, you can hire an expert to assist you.

Technical Specifications of the Automatic Capping Machine

To get a good machine, you need to know the exact type that you intend to use.

You need to have the technical specifications of the automatic capping machine at your fingertips.

In this section, you will learn about the specification to consider before making an order.

According to plant environment and operation considerations

The environment where you will install the automatic capping machine will also determine the type of machine to buy.

Your choice will further depend on the operational considerations that you intend to explore.

In case you intend to work with corrosive chemicals and explosive material.

You will go for a machine with materials that can withstand chemical corrosion.

The supplier should be capable of providing you with a machine that has the right frame style and electrical considerations.

The machine should also be capable of meeting the right quality standards set for different environments.

Conclusion

Was this guide useful?

I believe it will take care of all your capping machine needs.

The information in this guide will be the basis of your success in using a capping machine.

It will come in handy when you are making an order for a custom machine among other situations.

Wait no longer, it is time to revamp your operations with an automatic capping machine.

For free consultations and inquiries on automatic capping machine, contact us today.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!